Haskel manufactures the industry’s most reliable and comprehensive range of pneumatic or hydraulic-driven, high-pressure, liquid pumps, gas boosters, air pressure amplifiers and high-pressure valves and system components. A lasting reputation for quality, safety, and reliability, unrivalled expertise in high-pressure, liquid and gas transfer and pressurization technology, and the willingness to work closely with customers, drives Haskel to continually meet complex and critical challenges with innovative solutions. Their products are easy to install and control, and their compact size, minimal weight and ability to operate in any position makes them suitable for a wide range of mobile and fixed applications that involve generating, storing and controlling of high-pressure gases and liquids.

Gas-Transfer & Pressurization Solutions by Haskel Can Handle Challenging Applications

Flexible and efficient sources

These boosters are flexible, efficient sources for delivering high-pressure gases. Other examples available from Wainbee include helium gas compressor systems, nitrogen gas compressor systems, gas booster compressors, oxygen boosters (or minehunters), and modular component testing systems. Among the key advantages of these gas-transfer and -pressurization solutions:

• Oxygen or high-purity cleaning – Notable for their cleanliness, Haskel boosters can handle oxygen and other pure gases with no contamination risk. Oxygen-cleaned devices meet the Mil Spec 1330 standard.

• Multi-staging capability – One or more boosters of the same ratio can be plumbed in parallel and then in series with one of more boosters of the same ratio, for higher flow rates and pressures beyond the capability of a single gas booster.

• High flow rates at high pressures – When required, each booster can charge a receiver to an even higher pressure level, thereby storing an amount of gas available for fast release at a constant pressure through a pressure-reducing valve.

• Hydrogen | H2 – solutions engineered including refueling to 350 to 700 bars. Ensuring long-term leak-tight design and maintaining gas purity.

• Carbon Dioxide | CO2 – aerosol type gases can be boosted as a liquid or gas in controlled applications.

Another major benefit is cost savings. Most industrial gases are often delivered at pressures ranging from 2,000 to 2,600 pounds per square inch in steel cylinders. If the gas is to be used well below the supply pressure, the pressurized supply is piped and controlled easily to the point of use with simple valving. But if the gas needs to be used at higher pressures than that of the supply, it must be boosted. Haskel gas boosters can use all the gas from cylinders and other supply sources and boost it to the needed pressures and flows, which uses all the gas volume from the supply source.

Wainbee’s Recommendation of Haskel’s Gas Boosters Leads to First-ever Student-built Liquid Rocket Created to Cross the Kármán Line!

Few things are as awe-inspiring as watching a rocket blast off into the sky. Even more so if you helped build it—and, you’re still in college with shrinking access to already-limited resources.

For the students in Concordia University’s StarSailor project, that moment will be especially memorable—not just because their rocket will be the first student-built liquid-propellant rocket to pass the Karman line (thus officially reaching space), but also because of the challenge they face in filling up their nitrogen tank for testing and launch preparation.

Click here to read the full story.

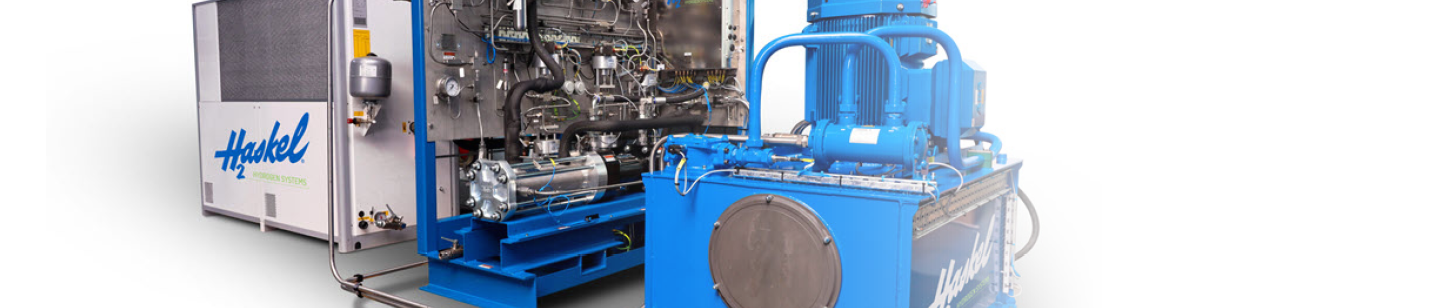

H-Drive Series of Gas Boosters by Haskel Suits Challenging Applications

The H-Drive represents the future of gas handling at high pressures. These instruments are built out of materials that major regulatory agencies have approved for safe lifetime continuous operation, and no other hydraulically driven boosters deliver flows as high or maintenance expenses as low. The unit has interchangeable modular gas sections with safety and reliability levels that comply with global standards for high-pressure generation and containment.

A key benefit is a unique seal design, which delivers gas-tight, non-contaminating compression with self-lubricating seals that help to keep gas clean. Constructed with serviceability and efficiency in mind, the H-Drive has a modular design that makes it simple for users to configure for different applications.

This device is offered as a unit or in a skid-mounted form, giving flexibility to system engineers. Among its other major features:

• ATEX and CE certifications;

• hydrogen-compatible materials, to prevent hydrogen embrittlement;

• minimum amount of boosters, while still complying with hydrogen fuelling-station needs;

• no start/stop issues;

• robust design, suitable for constant heavy-duty applications; and

• service and support available through a worldwide service network.

In addition to these advantages, the H-Drive series is more economical than diaphragm compressors are, and it is available as a turnkey booster compressor station or as booster modules for seamless incorporation into packages for manufacturers.

This hydraulically driven gas booster by Haskel sets a new standard in reliability, whether the user is working with hydrogen, natural gas, nitrogen, or helium, from alternative vehicle fuelling to tube trailer supply and helium blanketing. This technology ensures top performance throughout continuous heavy-duty applications, delivering high pressure whenever and wherever it is required.

Redefining What a Gas Booster Can Do For The Food & Beverage Industry

Haskel's Q-Drive Gas Compressor is ideal in the food industry for supercritical extraction, carbonation, food packaging, wine making, and more. Its ability to handle a variety of gases, including high purity grades, level of cleanliness and quiet operating sound levels, makes the Q-Drive Gas Compressor an ideal solution in clean environments.

An electric servo drive is key to its high efficiency and precise precision control. Electric servo motors are extremely reliable and have fewer moving parts that require less maintenance. Maintenance is made easier with self-monitoring and diagnostic capabilities that provide proactive maintenance notifications and system alerts.

Programming, remote monitoring, and on-the-fly adjustments are all facilitated by a sophisticated interface, and communication protocols enable interaction with other automation equipment.

Q-Drive reaches new levels of cleanliness, quietness, and efficiency

• Clean compression, quiet operation & infinite controllability

• Energy efficient, Environmentally friendly

• 100% duty cycle

• Small footprint—25% less square footage than an average HPU

• Less power consumption than hydraulic & air-driven boosters

• Easy maintenance with quick access and visual diagnostics

Q-Drive features a smart Human Machine Interface (HMI) for advanced monitoring and diagnostics

• Touchscreen programming, temperature monitoring & graphic display of system operation

• Interface between in-house automation systems

• Intelligent diagnostic control

• Reduced maintenance and increased up-time