Parker's global reach and capability to design, develop and manufacture Industrial and Mobile hydraulic products secures their place as the global leader in Motion Control. With manufacturing locations worldwide, they are well positioned to serve all their respective markets and deliver world class quality and technologically advanced products to satisfy today's customers’ needs.

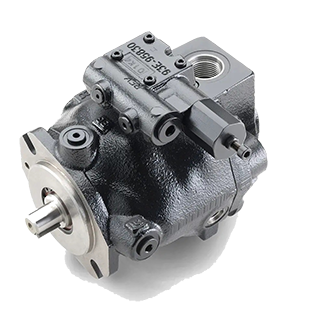

Parker’s P1/PD Controls: Powering Precision with Pump-monitoring Mastery

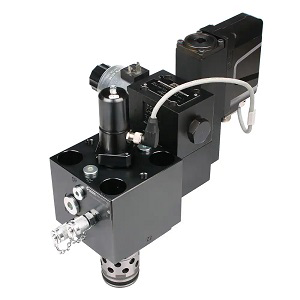

These Parker P1/PD electronic controls are powered by Graphical User Interface (GUI) software. The GUI enables monitoring of settings, system status, pressure, speed, temperature, and other pump data.

Loading and using the GUI software is easy once the P1/PD electronic control is set up. You can download the software from the Parker website to install it on your desktop computer.

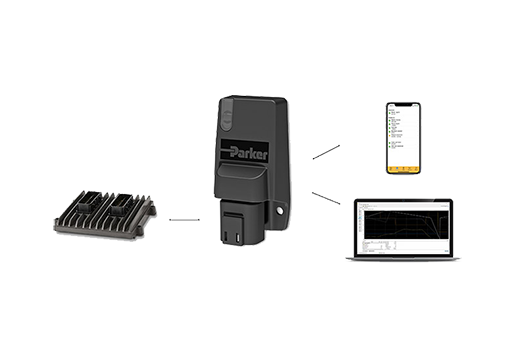

Parker IQAN® - Delivery the Best Electronic Control Systems

Best in Class Software

Superior machine functionality is the number one priority and that the way to get there shall be simple, fast and intuitive. The IQAN software has been developed over the last 20 years with a constant focus on user friendliness, simplicity and safety so that you can be number one to the market.

On all Devices

IQAN tools are available for PCs, tablets and smart phones. Advanced engineering and service tools are available for PC installation. Service tools are available in different versions down to the most basic versions of smartphone apps for iOS and Android.

Secure & Reliable

IQAN lets you protect your Intellectual Property with multiple encrypted access levels. With a well-defined structure for access levels you can make sure that all parts of your organization has access to service and maintain your machines for maximum up time.

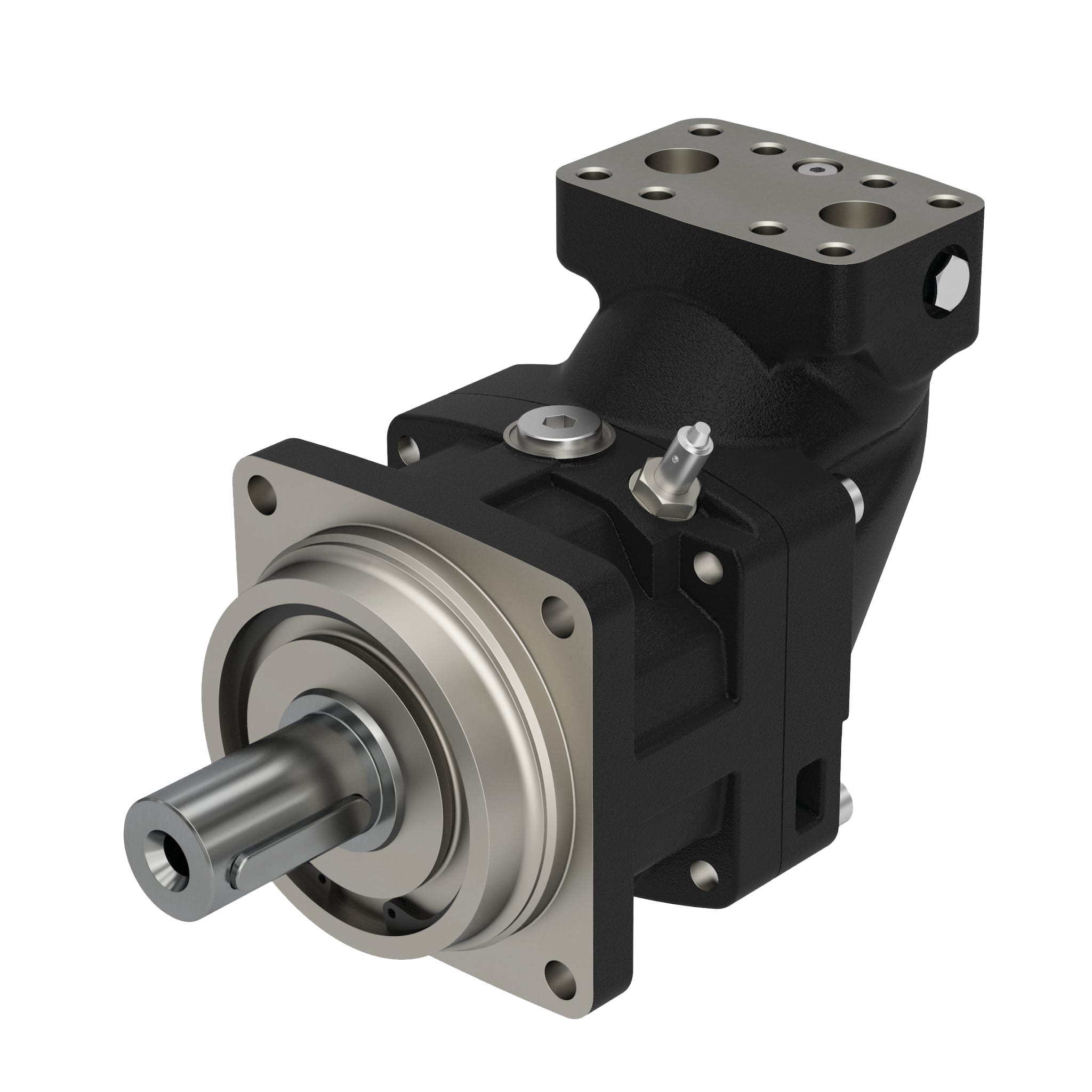

Bent-axis Pumps, Motors by Parker: Power Savings, Reliability, and Durability

One of the latest additions to this product family is the F10 series of bent-axis pumps and motors – recommended for mobile-equipment applications in agriculture, construction, mining, the marine sector, oil and gas, and transportation.

These medium-duty, fixed-displacement, bent-axis pumps and motors by Parker provide elevated performance in terms of power savings, reliability, and durability.

An upgrade of the F11 and F12 models produced by Parker’s Pump & Motor Division in Europe, the F10 series is available in seven displacements, from 30 to 125 cubic centimetres. The Parker Hannafin team has designed these units for both open- and closed-circuit transmissions, and they offer excellent efficiency, resulting in less power loss, due to the patented spherical piston concept.

The F10 series has the same design concept as the F11 and F12 heavy-duty series do, with double-tapered bearings and ring gear synchronization for the utmost durability and dependability. But the new models from Wainbee provide as much as 13 per cent smaller envelope size and 25 per cent lighter weight than the F12 equivalent, which means much simpler installation, while the spherical piston design allows high volumetric efficiency of up to 96 per cent.

These pumps and motors are likely the most efficient medium-duty units of their kind available on the market today. Parker focused on long service life and high reliability when developing the F10 series, with sustainability and low total cost of ownership as major considerations too. These models can substantially lower operating expenses by reducing power consumption, thereby supporting the goals of original-equipment manufacturers to reduce their emissions and adhere to future environmental standards.

The F10 group is available to customers in ISO, SAE, and cartridge models with flexible shaft options. In addition, Parker manufactures a broad selection of options for speed sensors and integrated valves to work with these products. Parker Hannifin is a Fortune 250 global leader in motion and control, having engineered technological breakthroughs for more than 100 years.

Parker Announces the VA Series of Next-generation Load Sensing Valves for Mobile Machinery

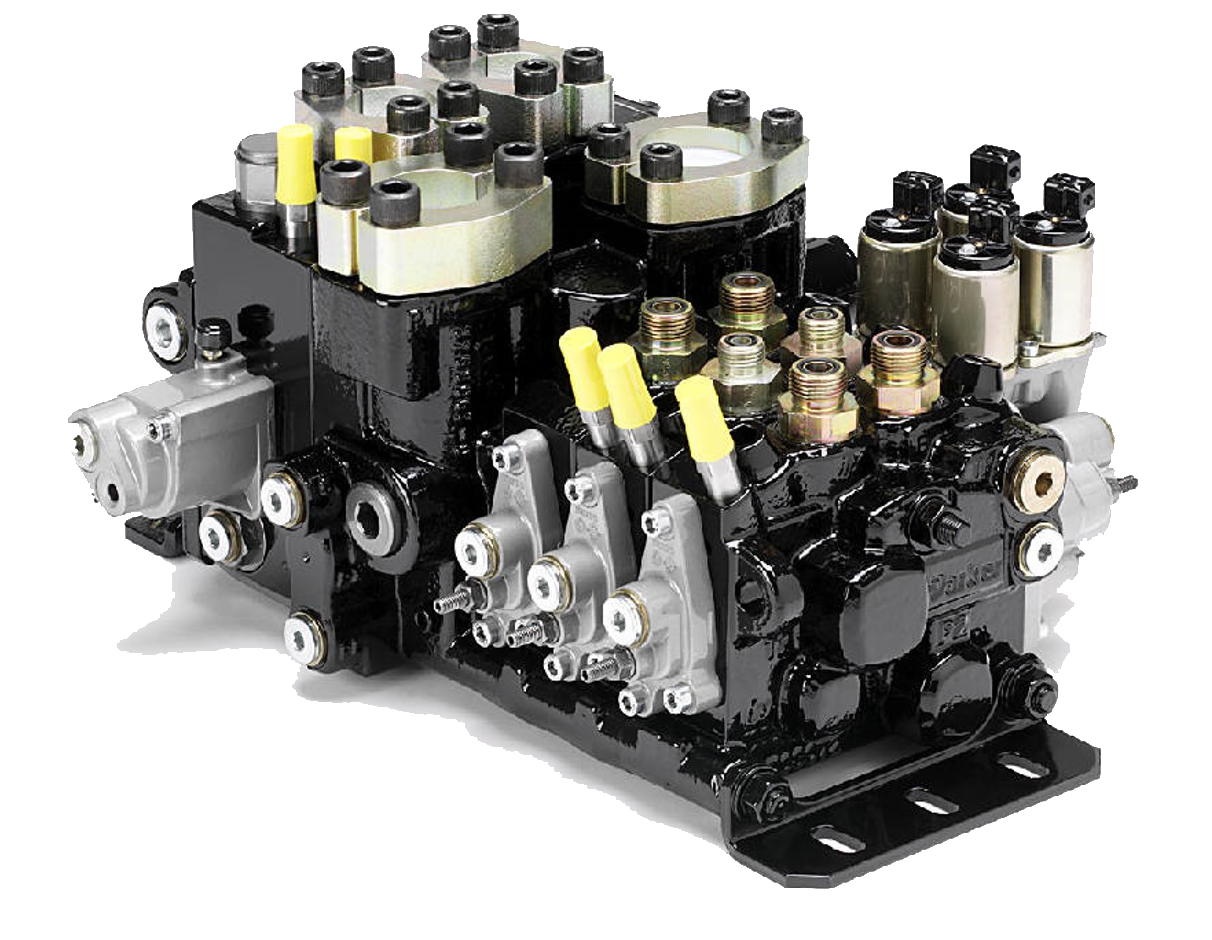

Parker's VA Series will consist of the next generation of pre-compensated, load sensing valves based on the long experience from L90LS and K220LS. Designed specifically for mobile machinery applications. Pre-compensated, proportional and load sensing - new LS valves with flow rates up to 450 l/min.

The VA series is a continuously growing portfolio of next generation proportional, pre-compensated, load sensing, mobile directional control valves. With a foundation of market leading high-end valves like K220LS and L90LS, VA Series is ensured to offer valves with enhanced properties regarding robustness, control precision, energy efficiency, modularity, and customization. Parker provides a variety of innovative products to help engineers solve inherent off-road industry challenge. These products ensure optimal performance, digital transformation, efficiency, and overall, help them build a better tomorrow. The new proportional cartridge throttle valves series TFP provide outstanding flow rates and minimized pressure losses. They control highest flows precise and with maximum dynamics in applications like die cast, hydraulic presses and injection molding. The active operated 2-way servo proportional valves with VCD® technology series TFP are outstandingly suitable for demanding applications where highest flows have to be controlled at maximum dynamics. The V16 Series is a new generation of variable displacement, bent-axis motors and a further development of the well-known V12 and V14 motor series. The new motors are available in 220 cc and 270 cc. Designed for both open and closed-circuit transmissions with a focus on high performance machines, the V16 has the ability of stroking to zero displacement. This capability provides superior fuel savings and a reduced environmental footprint.

Parker industrial solutions are available in Canada through Wainbee Limited, including a line of hydraulic valves. An example is the D1VW*ER Hazardous Environment Directional Control Valve. This is a tri-rated, explosion-proof directional control valve that meets the requirements for ATEX, IECEx, and CSA/UL certifications. The D1VW*ER is available in both single and dual solenoid options and comes standard with transient voltage surge suppressor diodes, as well as an extended manual override with boot.

Parker L90LS mobile valve is characterized by industry leading properties regarding robustness, control precision and energy efficiency. Parker L90LS is a sectional-built, pre-compensated, load sensing, directional control valve for mobile machinery. It has a wide range of selectable functions, offering great flexibility in terms of system structure in simple as well as advanced hydraulic system solutions. The L90LS can be equipped with manually operated, hydraulic or electrohydraulic spool actuators in any combination. Each valve section can be optimised for its particular function in the machinery, with a large range of spools, pressure relief valves, pressure compensators, signal pressure limiters and other performance-enhancing functions. Consult with Wainbee Experts today on how our L90LS solutions can help customers quickly meet their application requirements. Load Sense Valve

VA Series will be available in different sizes seamlessly combinable to offer a complete package for machinery where there are large variations in flow requirement.

Each valve size will also be available as stand-alone valves to cover low as well as high demanding applications regarding flow requirement.

Features & Benefits:

• Will be expanded with more sizes in terms of flow, combinable to cover varying flow demand in the same valve stack.

• Modular design providing wide range of functions and combination possibilities to suit any need, yet service friendly to simplify maintenance and repairs.

• Seamless integration of function manifolds specially designed with the customer’s specific needs in mind to reduce number of components and simplify the hydraulic system.

• Parker’s unique online configurator provides automatically created and instantly available code report, schematics, spare parts list, 3D model and 2D drawing to reduce development time.

Markets:

• Forestry Equipment

• Construction Equipment

• Material Handling Equipment

• Mining

Applications:

• Forwarders

• Forestry harvesters

• Forest cranes

• Harvesting heads

• Mining machines

• Drill rigs

• Loaders

• Dump trucks

• Excavators

• Construction machines

• Forklift trucks

• Material handling cranes

• Reach stackers and many more…Bring Greater Efficiency to Your Mining Equipment

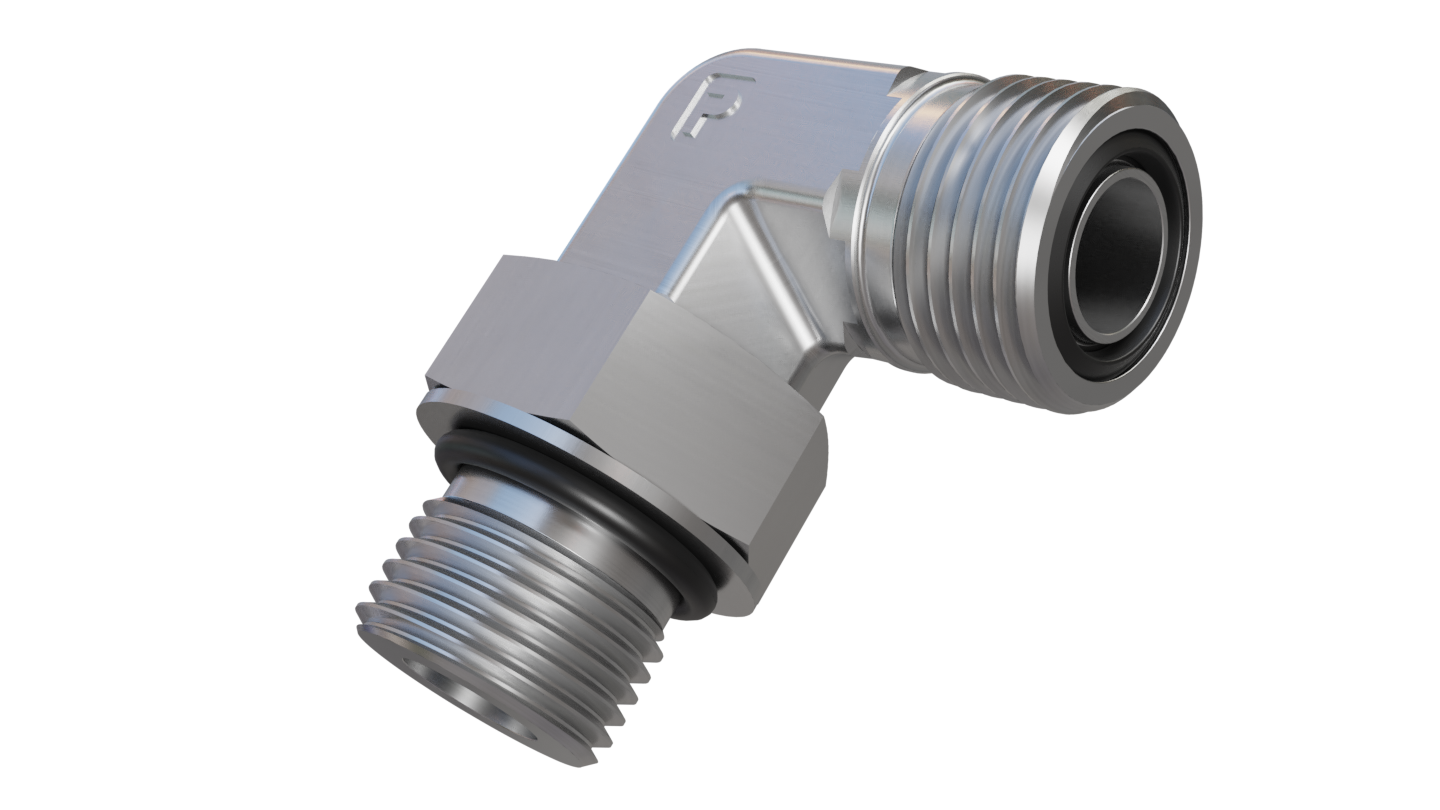

• Fast responsive controls

• Designed for severe applications

• Parker Tracking System (PTS)

• Easy service and replacement

• Seal retention ensured with Trap-Seal™

• 480 bar and 520 l/min

• Forged steel bowl Parker’s New Cartridge Valve: 2-Way Servo Proportional Valve with VCD® Technology

Thanks to the enormous flow rates combined with lowest pressure losses, they provide an almost unique energy density. This enables the use of smaller sizes and thus the design of size- and cost-optimized control manifold blocks. Moreover, the maximum performance is increasing. As a result, systems with significantly higher flow can be realized, e.g. with large die cast machines for the automotive industry.

Markets:

• Industrial

• Molding

Features/Benefits:

• Active operated 2-way servo proportional valve

• 7 sizes, NG25 up to NG100

• Cavity and mounting pattern according to ISO 7368

• Flow ranges up to 11100 l/min at 5 bar Δp

• Highest power density – saves typically one size when designing control manifold blocks and thus enables smaller blocks with the same performance

• High precision – for high quality products, minimum scrap rate and long machine lifetime

• Extremely fast step response – shortens material processing and thus cycle times

• 420 bar maximum operating pressure – increases performance in particularly demanding applications

• LVDT installed in the pilot chamber – protects from pressure peaks and thus increases reliability

• Short delivery time – no warehousing necessary

• Fail save position in case of electrical power down

Applications:

• Die cast

• General presses

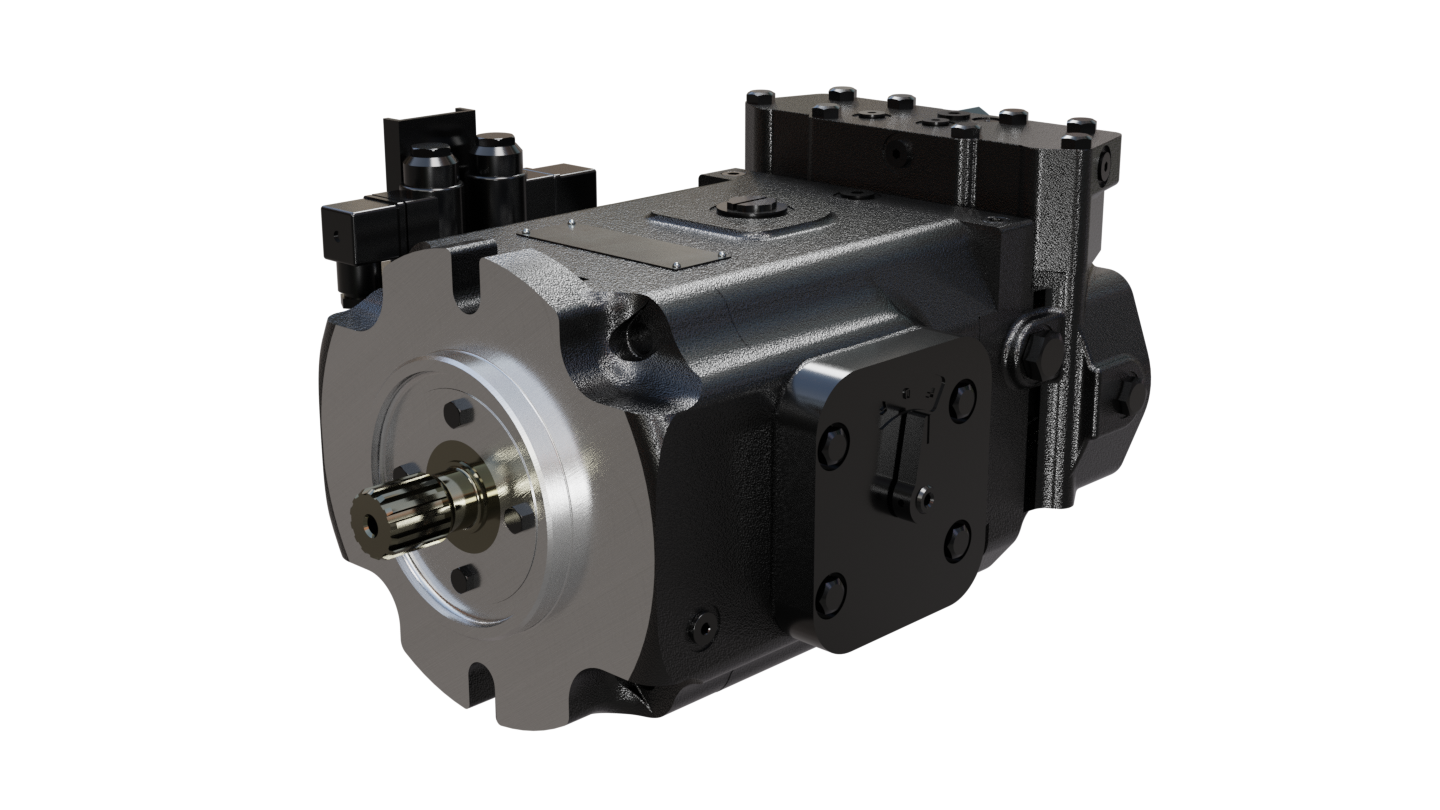

• Injection moldingV16 - The New Variable Motor from Parker!

New Variable Motor

Series V16 is a new generation of variable displacement, bent-axis motors.

A further development of our well known V12 and V14 motor series.

The new motors are avialable in 220 cc and 270 cc.

Fuel Savings and less CO2 Emissions

V16 is probably the most efficient variable bent-axis motors on the market.

Now with the ability of stroking to zero displacement.

This will give superior fuel savings and reduced environmental footprint.

Performance & Productivity

V16 high speed motors offer superior performance, outstanding efficiency and speed capability throughout the entire displacement range.

Parker Variable Motors Catalog (Series V12, V14, V16)

Featured Product: Directional Control Valve by Parker is Built for Hazardous Applications

Vertical or horizontal wiring installation

The D1VW*ER has indexable solenoid covers that enable either vertical or horizontal wire installation through the top of the four different side positions. This directional control valve by Parker also has an industry-leading operational temperature range, stretching from -54 to 70 degrees Celsius. The laser-etched QR code makes the device enabled through the Parker Tracking System, which allows access to critical data anywhere with Internet access.

Among the other standard features of this directional control valve from Wainbee:

• pressure of up to 5,000 pounds per square inch

• flow of up to 22 gallons per minute, depending on the spool

• availability in 120/60-110-50 VAC rectified (Y) 24 VDC (J)

• transient voltage surge suppressor diode for DC power

• broad range of spools and options that enables design of an unlimited amount of hydraulic circuits

• TVS diode

• compact, proven design that showcases the long-term experience Parker has in hydraulics

Parker recommends the D1VW*ER for use in oil and gas exploration, as well as aircraft ground support.

Technical specifications include the following: input voltage of 24 VDC; weight of 9.4 pounds; nitrile seal material; explosion-proof coils; hydraulic oil for fluid type; four-way, two-position function with open crossover; solenoid actuation type; and sub-plate mounting type. The connection type is explosion-proof with a configurable cable connection.

Wainbee supplies a complete selection of Parker products, in several categories. These include fluid connectors, pneumatic devices, valves, industrial and mobile hydraulics, automation products, and filtration solutions. Some come from the Parker domnick hunter and Racor divisions. Wainbee is a proud Canadian distributor offering diverse solutions for various industrial markets.

Wainbee Build Solutions: Mobile Directional Control Valves - Parker Series L90LS

Applications

Features & Benefits